Cold-Drawn Cold-Rolled Precision Seamless Steel Pipe Production Line

Introduction

The Precision Steel Pipe Factory, formerly known as Shanghai Steel

Pipe Factory, was built in 1958 and relocated into the Baoshan

major base of Baoshan Iron & Steel Co., Ltd. in 2012. Currently,

it¡¯s a dedicated precision seamless steel pipe production unit

affiliated to the Tube, Pipe and Bar Business Unit.

The Precision Steel Pipe Factory, formerly known as Shanghai Steel

Pipe Factory, was built in 1958 and relocated into the Baoshan

major base of Baoshan Iron & Steel Co., Ltd. in 2012. Currently,

it¡¯s a dedicated precision seamless steel pipe production unit

affiliated to the Tube, Pipe and Bar Business Unit.

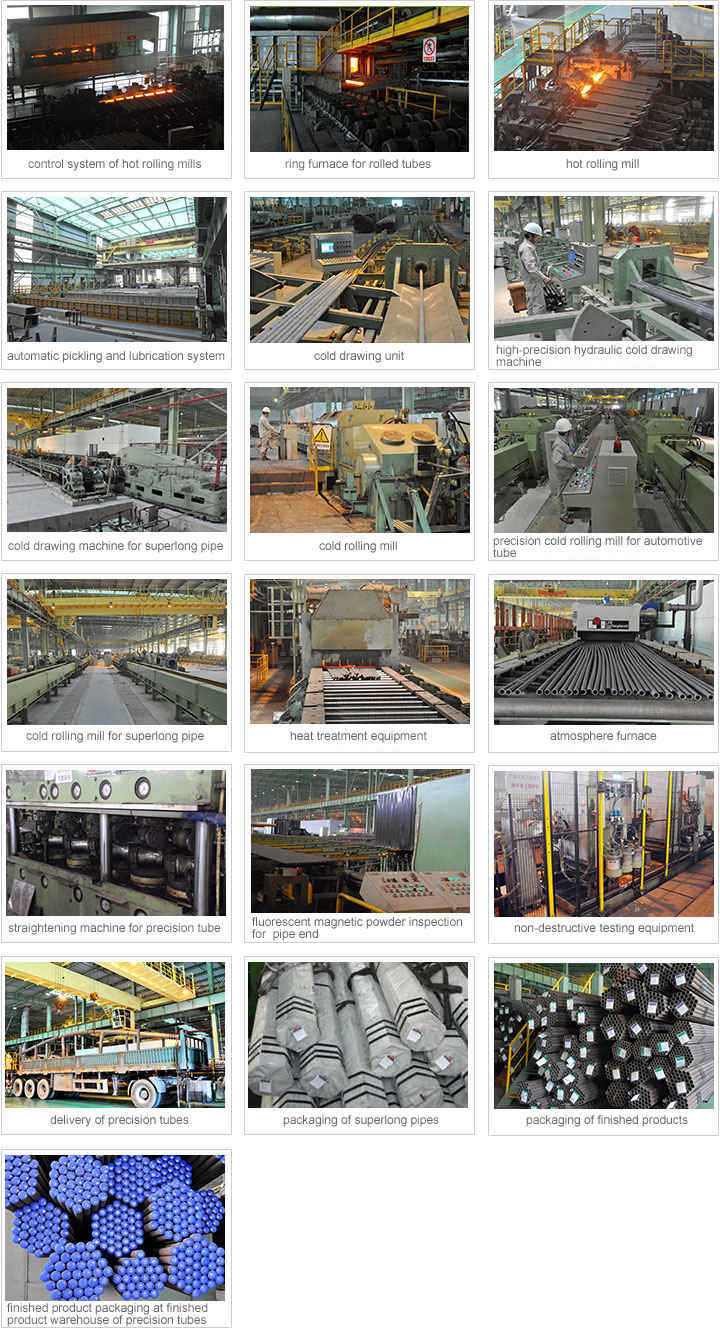

With more than 50 years of production experience, the Precision Steel Pipe Factory has now become a leading supplier with the most varieties of small-caliber precision steel pipes and tubes for power station boilers and the widest specification range in China. It has 10 cold drawing machines (3 tons to 120 tons), two of which are hydraulic cold drawing machines with a capacity of 90 tons, 13 cold rolling machines and state-of-the-art automatic equipment for pickling, lubrication, heat treatment and non-destructive testing.

>It has a designed annual capacity of approximately 80 thousand tons. Product specifications: diameter: 16 to 89.0mm; wall thickness: 2 to 16.0mm; maximum length: 24m. Major steel types (grades) available: quality carbon structural steel, alloy structural steel and standard steel grades corresponding to international standards.

Major products: precision seamless pipes and tubes for automobile, steel pipes and tubes for ultra-supercritical and supercritical boiler, optimized rifled tubes and superlong pipes. All the steel pipes and tubes available are produced in strict accordance with international, national, industrial and corporate standards. Besides, to meet special requirements of different customers, products can be produced and supplied at a level higher than what is required by national standards on technical parameters after special technical agreements have been entered into. Its products are sold both home and abroad.

The Precision Steel Pipe Factory has obtained the ISO9001 (GB / T19001) quality management system certification, the production license for steel pipes and tubes for boilers and pressure vessels from the General Administration of Quality Supervision, Inspection and Quarantine (AQSIQ) of the People¡¯s Republic of China, and the membership of China Cooperation Network of ASME Code Items (CACI). Besides, the factory has been recognized as one of China¡¯s major designated producers because of its leading product, the seamless steel pipe for power station high-pressure boiler, and both the seamless steel pipes for power station high-pressure boilers and the seamless steel pipes for medium- and low-pressure boilers have been honored with national silver medals.

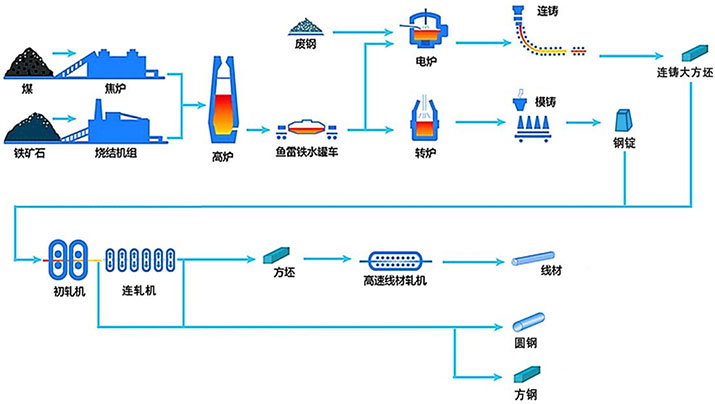

Production Process

Process Equipment