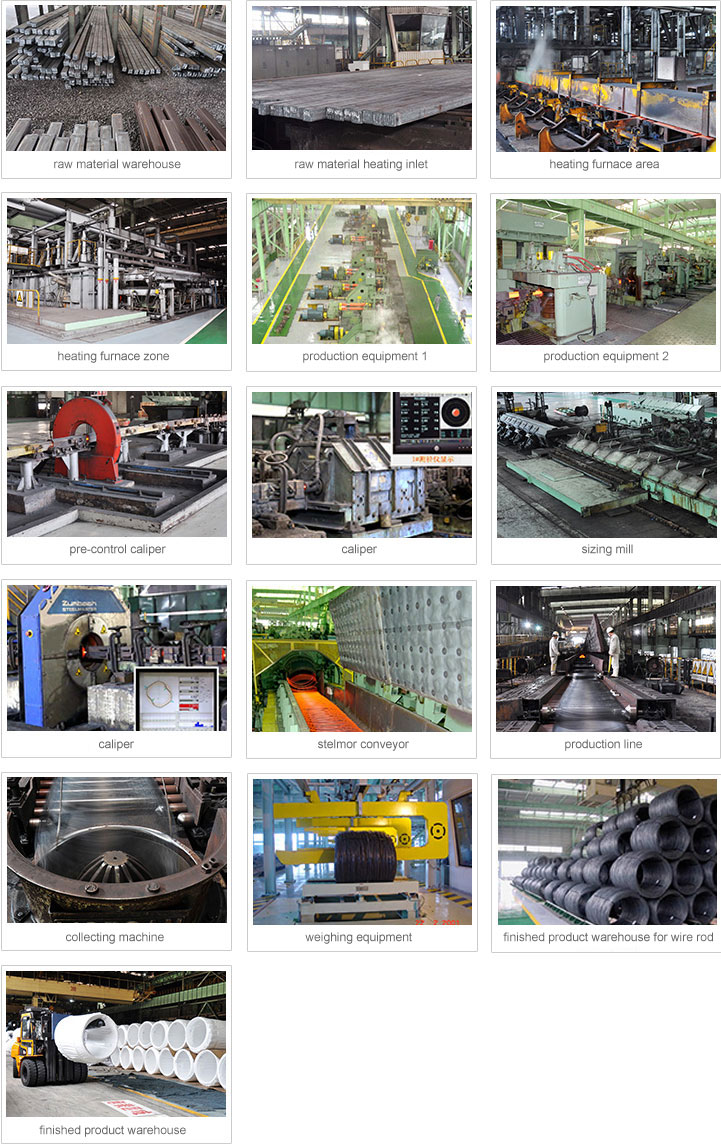

Wire Rod Production Line

Introduction

Located in the Baoshan major base of Baoshan Iron & Steel Co.,

Ltd., the wire rod mill was put into production in March, 1999.

This advanced production line absorbed various merits with its

main mechanical equipment imported from MORGAN (America), its main

electric equipment imported from ABB (Sweden), and its heating

furnace imported from STEIN (France). The designed annual

production capacity of the line was 400,000 tons and its actual

output has been up to 580,000 tons per year since 2001. The

production line consists of the walking beam furnace, the roughing

mill, the medium rolling mill, the pre-finishing mill, the

finishing mill, the reducing and sizing mill, the flaw detector,

the diameter gauge, the wire drawing machine, the Stelmor line and

the PF line, etc. The production line adopts the continuous

non-torsion controlled rolling technique and its product

specification covers from ¶’5mm to ¶’26mm of the bright wire rod.

Our main products include the tire cord steel, the spring steel,

the cold heading steel, the galvanized steel wires for bridge

cable, the high-carbon steel and the welding wire rod, etc.

Located in the Baoshan major base of Baoshan Iron & Steel Co.,

Ltd., the wire rod mill was put into production in March, 1999.

This advanced production line absorbed various merits with its

main mechanical equipment imported from MORGAN (America), its main

electric equipment imported from ABB (Sweden), and its heating

furnace imported from STEIN (France). The designed annual

production capacity of the line was 400,000 tons and its actual

output has been up to 580,000 tons per year since 2001. The

production line consists of the walking beam furnace, the roughing

mill, the medium rolling mill, the pre-finishing mill, the

finishing mill, the reducing and sizing mill, the flaw detector,

the diameter gauge, the wire drawing machine, the Stelmor line and

the PF line, etc. The production line adopts the continuous

non-torsion controlled rolling technique and its product

specification covers from ¶’5mm to ¶’26mm of the bright wire rod.

Our main products include the tire cord steel, the spring steel,

the cold heading steel, the galvanized steel wires for bridge

cable, the high-carbon steel and the welding wire rod, etc.

The wire rod production line focuses on the high quality and adopts the Baosteel Through-going Quality Contorl Management to realize optimized control of the whole process. The products quality has been constantly improved through the advanced quality control method.

The wire rod mill has got its main products, such as the tire cord steel, the spring steel, the cold heading steel and the galvanized steel wires for bridge cable widely applied in the state key construcion projects and by many well-known domestic enterprises. The aforementioned products have been honored with The State Technological Invention Award and The Shanghai Technological Invention Award for several times.

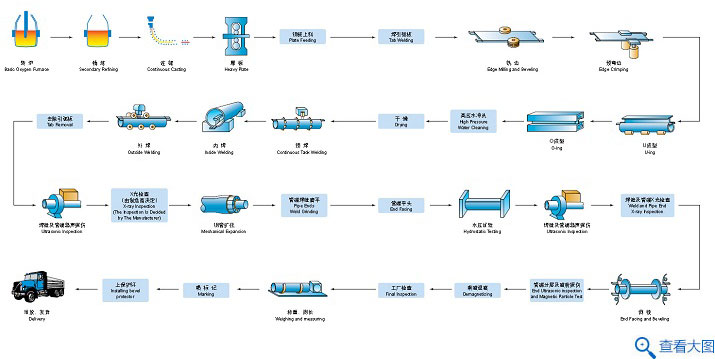

Production Process

Process Equipment