HFW (ERW) Production Line

Introduction

Located within the Baoshan major base of Baoshan Iron & Steel Co.,

Ltd., the HFW (ERW) pipe production line was put into production

in 2005.

Located within the Baoshan major base of Baoshan Iron & Steel Co.,

Ltd., the HFW (ERW) pipe production line was put into production

in 2005.

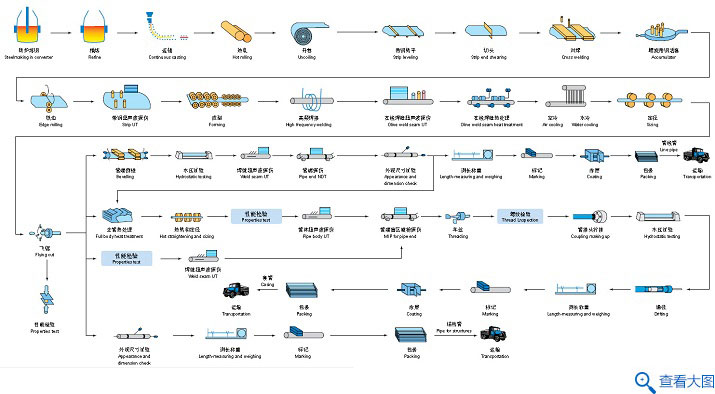

With its major equipment imported from SMS MEER (Germany) and EFD (Norway), it is the most advanced ERW pipe production line that integrates the state-of-the-art forming process, the high-power welding process, the fully-functional non-destructive testing process, the double heat treatment for welds, the full pipe body heat treatment equipment, and the computer-based full-process material flow tracking system. With an annual capacity of 300 thousand tons, it produces 180 thousand tons of line pipes, 90 thousand tons of casings and 30 thousand tons of structural pipes per year.

The HFW (ERW) pipe production line has obtained the Integrated Management System (IMS) (for Quality, Safety and Environment) Certification from BSI, the ISO 14001 certification from China Certification Center, Inc. (CCCI), and the Complete Measuring and Testing System Certification from the General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China (AQSIQ). Besides, it has also obtained the license from API to use the API 5CT and 5L marks and the license for producing welded pipe and pressure tubes as per GB/T 9711.2.

Production Process

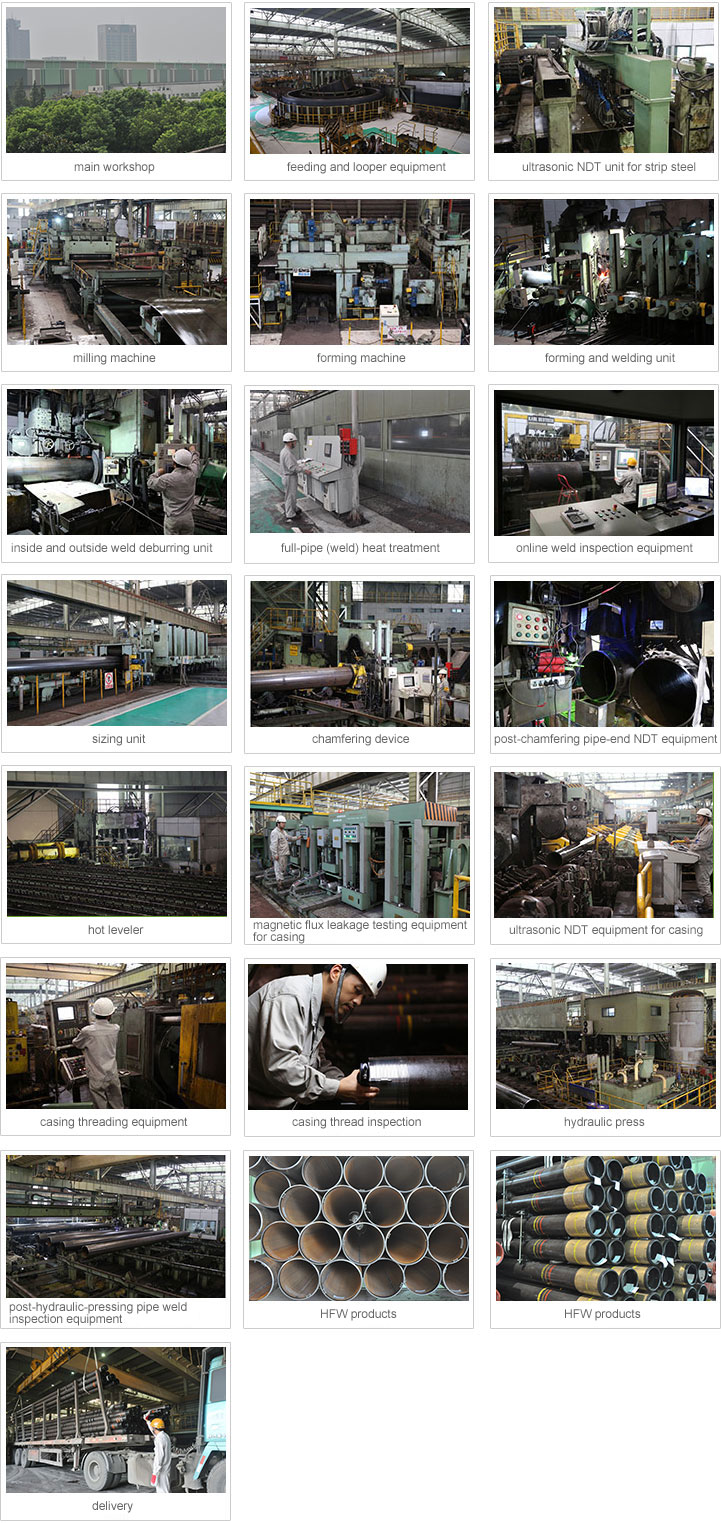

Process Equipment