UOE Production Line

Introduction

Located within the Baoshan major base of Baoshan Iron & Steel Co.,

Ltd., the UOE welded pipe production line was put into production

in 2006.

Located within the Baoshan major base of Baoshan Iron & Steel Co.,

Ltd., the UOE welded pipe production line was put into production

in 2006.

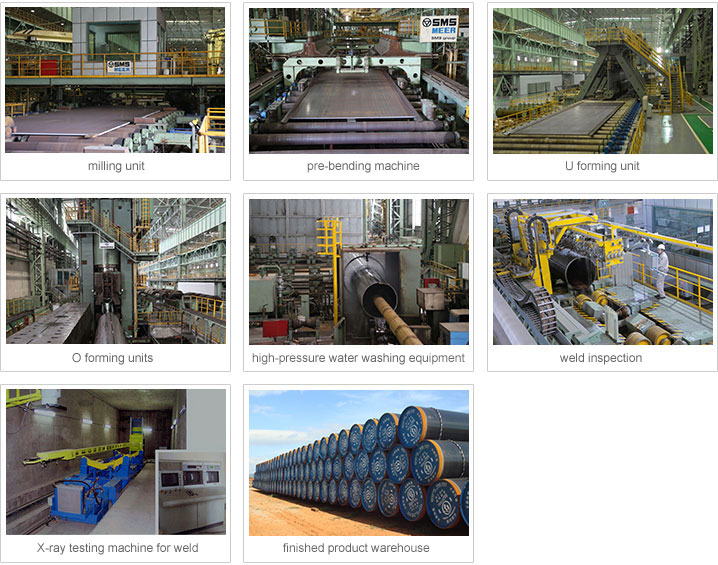

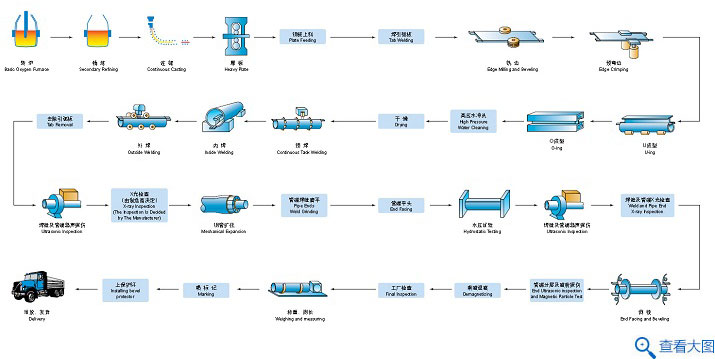

The UOE Welded Pipe Plant has different lines for forming, welding and finishing, etc., with its major equipment imported from Germany and Sweden. The major unit of the UOE welded pipe coating line is designed and manufactured by Socotherm based in Italy. With advanced equipment including the 2,350-ton U forming machine, the 72,000-ton O forming machine, the inside and outside submerged arc welding machine (five-electrode outside welding and four-electrode inside welding), the computer-based material flow tracking system, the automatic ultrasonic inspection equipment, the X-ray detection equipment, and the pipe end MPI and UI equipment, etc., this production line is currently a state-of-the-art UOE line with the worldí»s latest technologies and most powerful equipment capabilities. With a planned annual capability of 500 thousand tons of welded pipes and 370 thousand tons of coated pipes, it can offer products that are 508 to 1422mm in outer diameter, 6 to 40mm in wall thickness, and X42 to X100 in grade, which are suitable for submarine and onshore transmission of petroleum and natural gas under low temperatures and acidic conditions. Its products can be coated on both the inside and the outside (outside coatings include triple-layered polyethylene, triple-layered polypropylene, single-layered epoxy and double-layered, while inside coatings include drag-reducing and anti-corrosion coatings). Baosteelí»s UOE pipes are available in a wide variety, featured by high dimensional precision, good inside and outside surface finish, excellent steel purity with low contents of carbon, phosphorus, sulfur and other impurities, high impact toughness of pipe bodies and welds, excellent welding performance, as well as good product quality and onsite assembly welding quality.

Baosteel has got its UOE pipes widely applied in key international and domestic energy projects featured by complex geographical conditions, such as the East-West Natural Gas Pipeline Project, submarine pipeline projects, and slurry pipeline projects.

Its UOE pipes have also been certified and recognized by well-estalished certification authorities and well-known international companies such as API and Shell.

Production Process

Process Equipment