Seamless Tube

- Tubing&casing

- Drill Pipe

- High-Pressure Boiler Tube

- Line Pipe

- Tubes for Automobile

- Tubes for Gas Cylinder

- Tube for Perforating Gun

- High-Strength Structural Pipe

- Geological Drilling Pipe

- Pipe for Train Bogie

- Other Products

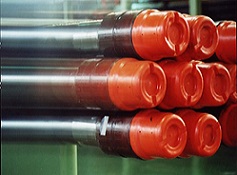

Tubing&casing

Baosteel OCTGs are widely used in Daqing Oilfield, Tarim Oilfield, Shengli Oilfield, Sichuan oil and gas fields with complicated geological conditions, and Bohai Bay Oil Field. Furthermore, its OCTGs are exported to many different countries in Europe, America, Middle East, Central Asia, and Southeast Asia. At present, Baosteel is capable of producing a whole series of OCTG products including tubings, casings and drill pipes. It can offer API standard products and non-standard products and has the capability to develop special threads and new grades with independent intellectual properties. The raw materials range from low-alloy steel through 13Cr martensitic stainless steel to top-end nickel-based alloy. Different categories of OCTG products have been gradually formed, including deep well series, anti-collapse series, anti-sulfur series, economical anti-CO2-corrosion series, and combinations of the above, to meet different needs for oil drilling and production under different complicated geological conditions.

Standards

API Spec 5CT, API Spec 5B, BG Series

Grade

H2S stress corrosion (SSC) resistance:BG55S¡¢BG55SS¡¢BG80S¡¢BG80SS¡¢BG90S¡¢BG90SS¡¢BG95S¡¢BG95SS¡¢BG110S¡¢BG110SS¡¢BG125S

CO2 corrosion resistance and CO2 + H2S corrosion resistance:BG55-1Cr¡¢BG80-1Cr¡¢BG80-3Cr¡¢BG90-3Cr¡¢BG95-3Cr¡¢BG110-3Cr¡¢BG125-3Cr¡¢BG80S-3Cr¡¢BG80SS-3Cr¡¢BG90S-3Cr

CO2 corrosion resistance and CO2 + H2S corrosion resistance:BG90SS-3Cr¡¢BG95S-3Cr¡¢BG95SS-3Cr¡¢BG110S-2Cr

Super 13Cr:BG13Cr-110¡¢BG13Cr-110U¡¢BG13Cr-110S

Nickel-based alloy:BG2250-110¡¢BG2250-125¡¢BG2242-110¡¢BG2830-110¡¢BG2235-110¡¢BG2532-110

Ultra-high anti-collapse::BG80TT¡¢BG95TT¡¢BG110TT¡¢BG125TT¡¢BG130TT¡¢BG140TT¡¢BG150TT¡¢BG160TT

High anti-collapse, suitable for sulfurous conditionsBG80TS¡¢BG95TS¡¢BG110TS

Heat resistant:BG80H-1¡¢BG90H-1¡¢BG100H-1¡¢BG110H-1¡¢BG80H¡¢BG90H¡¢BG100H¡¢BG110H

Threads

Bare Pipes::No Threading (Bare Pipes)

Standard threads::(NU) Non-upset tubing round thread, EU upset tubing round thread, SC casing short round thread, LC casing long round thread, BC casing buttress thread, IJ integrally joined

Special Threads £ºBGXC, BGT1, BGC,

Baosteel casing long round thread, SUPERMAX, SMAX-TS, STC-S,

HUYANG, BHC, BGT- YC, BG-BUTT, BG-PC / T, BG-BC, BG-FJ.

Customization is available upon users' special requirements.

Specifications

| Specifications |

API 5CT

series |

H2S resistance

series |

Economic series

of CO2 corrosion resistance |

Economic series of

CO2+H2S corrosion resistance |

13Cr series |

Nickel-based

alloy series |

Anti-sulfur,

high anti-collapse casing series |

High anti-collapse

casing series |

Special thread series | Direct connection series | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Tubing | 2 3/8" | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | |||

| 2 7/8" | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ||||

| 3 1/2" | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ||||

| 4" | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | |||

| 4 1/2" | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ||||

| Chemical properties | 4 1/8" | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì |

| 4 1/2" | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | |

| 5" | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ||

| 5 1/2" | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | |

| 6 5/8" | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ||

| 7" | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ||

| 7 5/8" | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | |||

| 8 5/8" | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | |||

| 9 5/8" | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ¡Ì | ||||

| 10 3/4" | ¡Ì | ¡Ì | ¡Ì | ¡Ì | |||||||

| 11 3/4" | ¡Ì | ||||||||||

| 13 3/8" | ¡Ì | ||||||||||

| 16" | ¡Ì | ||||||||||

| 18 5/8" | ¡Ì | ||||||||||

| 20" | ¡Ì | ||||||||||

Chemical Composition

For more details, Please see Product Manual ...

Mechanical Properties

For more details, Please see Product Manual...

Drill Pipe

aosteel is the only Chinese steel manufacturer with a complete drill pipe production process from steelmaking, rolling, upsetting, heat treatment, straightening, NDT, and friction welding till completion of drill pipes. Since it started production of drill pipes in 1989, Baosteel has, through 25 years of production experience, overcome a series of critical technical challenges hindering the production of drill pipes, such as steel purity, MIU length of internal taper, impact toughness and straightness. Starting from production of API drill pipes, it has now expanded to produce high-end non-standard drill pipes. Through its launches of new products such as ultrahigh-strength, ultrahigh-toughness, super-large-displacement, super 13Cr, sulfur-resistant, BGDS high anti-torsion, BGST super high anti-torsion, and NC52 non-standard drill pipes, it has been able to develop advanced drill pipe production processes that meet complicated requirements for drilling deep wells, ultra-deep wells, directional wells, and extended reach wells. For example, Baosteel products were successfully used in Tarim Oilfield to break the record of the world's deepest well by deveolping a 7,620-meter well and a 8,023-meter well in a row. Besides, Baosteel also created the world record of horizontal directional crossing of 2,350 meters, making its drill pipe products among the world's leaders. At present, apart from wide application in domestic oilfields, Baosteel drill pipes are also sold to other countries and regions such as the United States, Canada, Russia, the Middle East and Southeast Asia.¡£

Standards

API 5D¡¢BG series

Grade

API products:E¡¢X¡¢G¡¢S

Ultra-high-strength:BGD150

Acidic conditions:BGD95U¡¢BGD95MS¡¢BGD95SS¡¢BGD105MS,BGD105SS

Threads

HDD-BGF2.46Threads ¡¢HDD-BGF3.60Threads ¡¢HDD-BGF3.96Threads ¡¢HDD-BGF3.103Threads ¡¢HDD-BGF4.103Threads ¡¢HDD-BGF5.48Threads

Specifications

23/8in~65/8in

Chemical Composition

For more details, Please see Product Manual ...

Mechanical Properties

For more details, Please see Product Manual ...

High-Pressure Boiler Tube

Baosteel boiler tubes are widely used for heating boilers and power station boilers. With its production in conformity with international standards such as DIN, ASTM, ASME, EN, and JIS as well as domestic standards, Baosteel offers a wide variety of grades (low, medium and high pressure) and provides hot rolling, cold drawing and cold rolling processes. It can produce superlong and high-pressure tubes with grooves on inside surfaces. Baosteel applies the protective gas heat treatment process for finished products, so its steel tubes have stable properties and good surface quality. Its long-term partners include Shanghai Electric Group (Shanghai Boiler Works), Dongfang Boiler Group Co., Ltd. (DBC), Babcock-Hitachi Dongfang Boiler Co., Ltd., and Babcock Wilcox Beijing Company Limited.

Standards

GB, ASME, ASTM, EN 10216-2, DIN 17175, JIS

Grades

Carbon steel::10¡¢20¡¢20G¡¢20MnG¡¢25MnG¡¢SA-106£¨include:B¡¢C£©¡¢SA-192¡¢ SA-210£¨include:A1¡¢C£©¡¢P265GH¡¢P195GH¡¢P235GH¡¢St35.8¡¢St45.8

Mo alloy::15MoG¡¢20MnG¡¢SA-209£¨include:T1¡¢T1a¡¢T1b£©¡¢15Mo3¡¢16Mo3

Cr-Mo alloy steel::12CrMoG¡¢12Cr2MoG¡¢12Cr1MoVG¡¢15CrMoG¡¢10Cr9MoCNb¡¢ SA213£¨include:T11¡¢T22¡¢T24¡¢T91£©¡¢12Cr1MoV¡¢14MoV63¡¢10CrMo910¡¢X10CrMoVNb91¡¢10CrMo5-5¡¢13CrMo4-5

Cr-Mo-W alloy steel::12Cr2MoWVTiB¡¢SA213£¨include:T23¡¢T92¡¢T122£©¡¢SA-214T911

martensitic stainless steel::TP304~346£¨include H£©¡¢S30432¡¢TP310HCbN

Specifications

Outer diameter: 16 ~ 457mm; wall thickness: 2.0 ~ 55mm

Chemical Composition

For more details, Please see Product Manual ...

Mechanical Properties

For more details, Please see Product Manual...

Line Pipe

Baosteel seamless line pipes are widely used in petroleum and natural gas industries for transmission of media such as gas, water, oil, and slurry (liquid mixture), applicable in both terrestrial and marine environments to address complicated working conditions such as low temperature, acidity, and huge drop height. Besides, Baosteel can also develop economic grades (steel types) for users to meet their special requirements. For instance, Baosteel partnered with Northwest Bureau to develop the 1Cr seamless line pipe, which achieved a good balance between cost efficiency and corrosion resistance and was highly recognized by users. The subsea line pipes supplied by Baosteel for Nanhai Liwan Deepwater Pipeline Project (1,500 meters) also won users' recognition because of their excellent pipe-end dimensional accuracy and weldability which facilitated the onsite automatic welding process and enhanced the efficiency of pipelaying.

Standard

API SPEC 5L¡¢ISO 3183¡¢GB/T 9711¡¢DNV-OS-F101

Grade

B, BN, BNS, BNO, X42 ~ X60 (with suffixes containing N, NS, NO, Q, QS, QO), X65 ~ X80 (with suffixes containing Q, QS, QO), L245 ~ L415 (with suffixes containing N, NS, NO, Q, QS, QO), L450 ~ L555 (with suffixes containing Q, QS, QO), DNV SMLS 415, DNV SMLS 450, and other standard-specified grades.

Specifications

140 seamless steel tube mill: OD Range(mm):31.8~200 Wall Thickness Range(mm):3.5~30

Yantai Baosteel Pipe Co.Ltd,: OD Range(mm):219~460 Wall Thickness Range(mm):7~55

Precision Seamless Steel Pipe Mill: OD Range(mm):16~89 Wall Thickness Range(mm):2~16

Chemical Composition

For more details, Please see Product Manual ...

Mechanical Properties

For more details, Please see Product Manual...

Tubes for Automobile

Tubes for automobile are used for manufacturing auto axles and housings. Partners include Qiqihar Railway Rolling Stock Co., Ltd., China Railway Materials Shanghai Company Limited, Zhongche Group Jinan Vehicle Co., Ltd., and Shenyang Locomotive and Rolling Stock Co., Ltd. CNR Group.

Standard

YB/T 5035 Standard Standard of China Metallurgical Industry

GB/T 8162 Standard China National Standard

MAL 010 Baosteel Delivery Technical Requirement

Grade

45¡¢45Mn2¡¢25MnCr¡¢20Mn2

Specifications

Hot-rolled seamless: outer diameter: 48 ~ 219mm; wall thickness: 5 ~ 22mm

Cold drawn cold rolled: outer diameter: 20 ~ 90mm; wall thickness: 1.25 ~ 10.7mm

Chemical Composition

For more details, Please see Product Manual ...

Mechanical Properties

For more details, Please see Product Manual...

Tubes for Gas Cylinder

Product Overview

Seamless steel gas cylinders are high-pressure vessels for storing compressed gases. The requirement on their safety performance is relatively high, and the requirement on steel quality is even stricter. Through the drawing process, Baosteel steel billets for gas cylinder can be used to manufacture seamless gas cylinders which are better than steel gas cylinders in terms of comprehensive performance and reliability. Baosteel is the first Chinese manufacturer to successfully develop gas cylinder steel with working pressure up to 30MPa, and it is superior to other domestic steel manufacturers in terms of technological and quality levels.

Standards

GB 18248

Grade

34Mn2V¡¢30CrMo¡¢34CrMo4¡¢34CrMo4-H

Available Specifications

Outer diameter: 88.9 ~ 457mm; wall thickness: 4 ~ 25mm

Chemical Composition

For more details, Please see Product Manual ...

Mechanical Properties

For more details, Please see Product Manual...

Tube for Perforating Gun

Baosteel tubes for perforating gun are specially designed for manufacturing perforating gun bodies for oil and gas wells. The outer diameters range from 60.3mm to 178mm, and major grades include 32CrMo4, and BG110P-BG150P. With stable performance and dimensional accuracy, Baosteel tube for perforating gun has established a good reputation among users. Partners include the Supplies Department of Sinopec Shengli Oilfield Branch, China Oilfield Services Limited (COSL), Sichuan Petroleum Perforating Equipment Co., Ltd., and Pan Union Steel Trading Limited.

Standard

Q/BQB 232 Standard Baosteel Corporation Standard

Grade

32CrMo4¡¢BG110P¡¢BG125P¡¢BG130P¡¢BG140P¡¢BG150P¡¢BG155P

Specifications

Outer diameter: 60.3 ~ 178mm; wall thickness: 5 ~ 13mm

Chemical Composition

For more details, Please see Product Manual ...

Mechanical Properties

For more details, Please see Product Manual...

High-Strength Structural Pipe

Based on stable raw material supplies and powerful quality assurance, Baosteel high-strength structural pipes have excellent strength, toughness, brittle fracture resistance, and weldability. Baosteel can also recommend appropriate welding processes to achieve better product performance. S770QL and S890QL are the latest high-strength mechanical structural pipes developed by Baosteel. Featured by higher load capacity and lighter weight, these products are widely applied in the fields of construction machinery and structural steel construction. Partners include Manitowoc, Xuzhou Heavy Industries, Sany Science and Technology, Shanghai Co., Ltd. and other well-known domestic and international companies.

Standards

Technical standard applicable to seamless pipes: GB / T8162-2008.

Grade

S770QL Grade£ºFGS78WV¡£

S890QL Grade£ºFGS90WV¡£

Specifications

Hot-rolled seamless: outer diameter: 38 ~ 457mm; wall thickness: 4 ~ 55mm.

Cold-drawn cold-rolled: outer diameter: 21 ~ 89mm; wall thickness: 2 ~ 16mm.

Chemical Composition

For more details, Please see Product Manual ...

Mechanical Properties

For more details, Please see Product Manual...

Application

As S770QL and S890QL are featured by excellent strength, toughness, brittle fracture resistance and weldability, they can make steel pipe walls thinner, reduce self-weight of structural parts, lower processing and installation costs, and cut residual stress, thus producing structural parts that low-strength steel cannot make.

S770QL and S890QL high-strength engineering machinery structural steel pipes can also be used in the following fields:

Engineering machinery: structural parts for cranes.

Steel structural components:

Hydraulic props, bridges, offshore platforms, civil engineering and shipbuilding. 9. As S890QL is featured by excellent strength, toughness, brittle fracture resistance and weldability, it can make steel pipe walls thinner, reduce self-weight of structural parts, lower processing and installation costs, and cut residual stress, thus producing structural parts that low-strength steel cannot make.

Geological Drilling Pipe

Baosteel geological drilling pipes are used for the industry of geological drilling and geological prospecting, and available grades include DZ40, DZ50, DZ60, STM-R780, BG850ZT, etc. The product is featured by good dimensional accuracy, excellent machining performance, and stable mechanical properties and has been widely recognized by the domestic geological sector. Partners include Tangshan Jinshi Superhard Material Co., Ltd., Hebei Xuanhua Zhongyuan Machinery Manufacturing Co., Ltd., Guangdong Geological Goods & Materials Corp., and Guizhou Geology & Mineral Materials General Company.

Standard

Q/BQB 230 Standard Baosteel Corporation Standard

YB 235 Standard Standard of China Metallurgical Industry

YB/T 5052 Standard Standard of China Metallurgical Industry

Grade

45MnB¡¢50Mn¡¢40Mn2¡¢40Mn2Si¡¢45MnMoB¡¢STM-R780¡¢DZ40¡¢DZ50¡¢DZ60

Specifications

Hot-rolled seamless: outer diameter: 42 ~ 178mm; wall thickness: 5 ~ 14mm.

Cold drawn cold rolled: outer diameter: 55.5 ~ 75mm; wall thickness: 2.5 ~ 7.5mm.

Chemical Composition

For more details, Please see Product Manual ...

Mechanical Properties

For more details, Please see Product Manual...

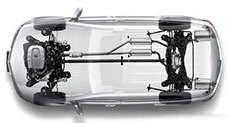

Pipe for Train Bogie

Baosteel pipe for train bogie is a new product that Baosteel developed in cooperation with the Ministry of Railways. A high-quality steel pipe specially developed for domestic freight train steering systems, it can work well within the ambient temperature range from £50¡æ to +70¡æ. When normal temperature is restored after it has been placed in a thawing unit at +110¡æ for three consecutive hours, it can still maintain its original working properties.

Standard

BEGG011¡¢Use supply agreement

Grade

A519-1010¡¢CR-1¡¢SMA490BW

Specifications

48¡Á5¡¢203x11¡¢89.1X20¡¢139.8X10¡¢205X13¡¢219X16

Chemical Composition

For more details, Please see Product Manual ...

Mechanical Properties

For more details, Please see Product Manual...

Other Products (Pipe and Tube for Ship, Insulating Tubing, Pup Joints, Refining Pipe and Tube, etc.)

Baosteel pipe and tube for ship: standards: EN 10305-4-2003, EN 10305-4-2003\GB/T 5312-1999; grades: 490, 410, St37.4, St52.4; outer diameter: 14 ~ 325mm; wall thickness: 2 ~ 15mm.

Baosteel insulating tubing: standards: API SPEC 5CT, Q/BQB 234-2003; grades: BG110H, N80-Q; outer diameter: 60.3 ~ 114.3mm; wall thickness: 4.83 ~ 6.45mm. Special varieties, specifications, grades can be made available through consultations and negotiations.

Insulated Tubing

Standard

Q/BQB 234 Standard Baosteel Corporation Standard

Grade

N80¡¢BG80H¡¢BG110H

Use

For producing viscous oil

Specifications

Hot-rolled seamless: outer diameter: 38 ~ 457mm; wall thickness: 4 ~ 55mm

Cold-drawn cold-rolled: outer diameter: 21 ~ 89mm; wall thickness: 2 ~ 16mm

Chemical Composition

For more details, Please see Product Manual ...

Mechanical Properties

For more details, Please see Product Manual...

Pipe and Tube for Ship

Standard

GB/T 5312 Standard China National Standard

Grade

320¡¢360¡¢410¡¢460¡¢490¡¢440

Use

For manufacture of boiler, superheaters for ships, and pressure system pipelines

Ship regulation

CCS Rules for Classification and Construction of Ships

LR Rules and Regulations for Classification of Ships

BV Rules for Classification of Ships

DNV Rules for Classification of Ships

GL Rules for Classification and Construction

Chemical Composition

For more details, Please see Product Manual ...

Mechanical Properties

For more details, Please see Product Manual...