Development History

Non-oriented electrical steel

Just as its name implies, the non-oriented electrical steel is featured by magnetic isotropy (otherwise known as isotropic electrical steel) is widely applicable to the manufacturing of all sorts of electrical motors and electronic transformer cores. In China, the consumption of non-oriented electrical steel represents around 90% of the total consumption of electrical steel.

Just as its name implies, the non-oriented electrical steel is featured by magnetic isotropy (otherwise known as isotropic electrical steel) is widely applicable to the manufacturing of all sorts of electrical motors and electronic transformer cores. In China, the consumption of non-oriented electrical steel represents around 90% of the total consumption of electrical steel.

Important milestones in development of non-oriented electrical steel :

During the period from 1882 to 1900 a British expert, R. A. Hadfield, found through his research that iron loss could be significantly reduced if a certain amount of silicon was added into steel;

In 1903 America and Germany started to produce hot-rolled silicon steel sheets to initiate the commercial production process of silicon steel;

In the early 1940s the production of cold-rolled non-oriented silicon steel started;

In 1954 Taiyuan Iron & Steel (Group) Co., Ltd. (TISCO) started to produce hot-rolled silicon steel to start the production of silicon steel in China;

In the 1980s all the countries stopped producing hot-rolled silicon steel except China;

In 1979 WISCO introduced technologies from Nippon Steel Corporation, a Japanese company, to start producing cold-rolled non-oriented silicon steel, which initiated the production of cold-rolled silicon steel in China;

In 2000Baosteel introduced the technologies from Kawasaki Heavy Industries, Ltd. (now known as JFE), a Japanese company, to start producing medium and low grade cold-rolled silicon steel;

In 2008Baosteel independently developed technologies and equipment for producing high-grade and high-efficiency non-oriented silicon steel and became the world’s first manufacturing to realize a comprehensive improvement of the product within the shortest time.

Grain-oriented flat-rolled electrical steel

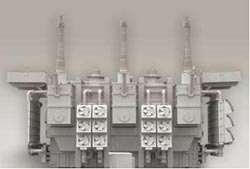

The grain-oriented silicon steel is a kind of electrical steel with its easy magnetization direction parallel to the rolling direction and a silicon content of around 3%. The grain-oriented silicon steel can be divided into two major categories including common grain-oriented silicon steel and high magnetic induction grain-oriented silicon steel. It is mostly applicable to the field of power transmission (such as transformers) and is an important functional metal material in the electrical power, electronic and military industries.

The grain-oriented silicon steel is a kind of electrical steel with its easy magnetization direction parallel to the rolling direction and a silicon content of around 3%. The grain-oriented silicon steel can be divided into two major categories including common grain-oriented silicon steel and high magnetic induction grain-oriented silicon steel. It is mostly applicable to the field of power transmission (such as transformers) and is an important functional metal material in the electrical power, electronic and military industries.

Grain-oriented silicon steel has long been known as the art work of steel, which are technologically sophisticated and technically complicated. Whether to master the technology for producing the grain-oriented silicon steel has always been used as an indicator of a steel manufacturer’s technological capability. Before 2000, in China, only WISCO had the ability of volume production of cold-rolled grain-oriented silicon steel with an annual capacity of around 100 thousand tons, only satisfying 30% of the demand of the domestic market. The remaining gap was mainly dependent on import. As a result, the development of the power industry was restricted. With the development of the low-carbon economy and the constant rise of energy costs, ultrahigh-voltage, large-capacity, low-loss and intelligent power transmission became a world trend. Therefore, the Chinese transformer industry was in pressing need of high-grade grain-oriented silicon steel. As the technology for manufacturing high-grade grain-oriented silicon steel was only in the possession of a limited number of companies who considered such technology as strictly confidential and refused to transfer it. The Chinese people must break through such technological blockade through independent research and development.

Early in 1997,through its pre-research on grain-oriented silicon steel in its own laboratory,Baosteel gained some initial insight into the characteristics of the manufacturing processes for the three major categories of grain-oriented silicon steel (high, medium and low temperature), explored the feasibility of technical routes and trial-produced qualified laboratory samples. On such basis, Baosteel started to engage its key in-house research and development personnel in massive development of low-temperature high magnetic induction grain-oriented silicon steel.With its breakthroughs in laboratory equipment and technology as well as system testing technology as the departure point, Baosteel succeeded in developing the key technology for manufacturing low-temperature high magnetic induction grain-oriented silicon steel. Afterwards, Baosteel began to build its production line for grain-oriented silicon steel.

The construction of Baosteel’s grain-oriented silicon steel production line is divided into three phases. So far, its production capacity of grain-oriented silicon steel has reached 200 thousand tons. By 2014, its annual capacity of grain-oriented silicon steel will reach 300 thousand tons.