EOE Manufacturing Process

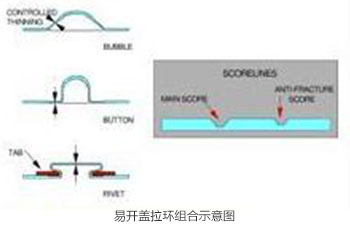

The EOE manufacturing process can be divided into two major steps. First, make the base end. Then, combine the end with the pull tab to form an EOE.

①Base End Manufacturing Process

Scroll shearing/slitting ¡ú feeding ¡ú Base end making ¡ú Curling ¡ú Lining ¡ú Drying ¡ú Selection ¡ú Packing

②Base End and Pull Tab Combination Process

Bubbling ¡ú Sizing ¡ú Rivet ¡ú Ridge ¡ú Groove ¡ú Connection ¡ú Die¡ú End

top shaping ¡ú Online photodetection ¡ú Package counting. The process

from blistering to rivet is shown as Figure 2.11.

③Ring Pull Tab Manufacturing Process

③Ring Pull Tab Manufacturing Process

Manufacturing process: Punching, guide hole ¡ú countersink, punching ¡ú punching countersink ¡ú vacancy ¡ú ring pull cutting ¡ú pre-rolling ¡ú vacancy ¡ú forming ¡ú 90¡ã bending ¡ú vacancy ¡ú rivet punching ¡ú vacancy ¡ú curling ¡ú rivet punching and sizing

Quality control is in accordance with the requirements of the process drawing: Check ring pull tabs for dimensions and shape at each step of the production process, and pay attention to the condition and overall operation of guide pins.