Phosphating technology

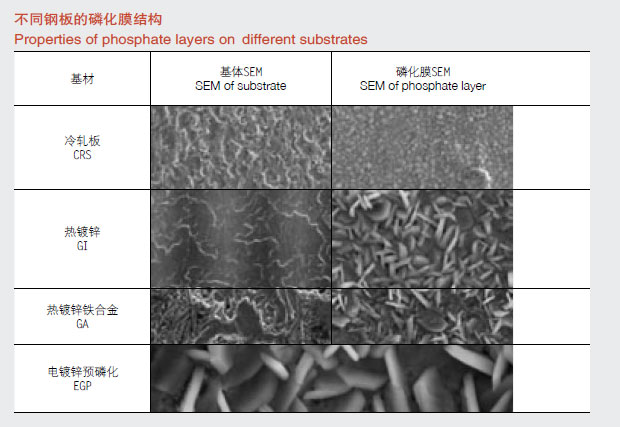

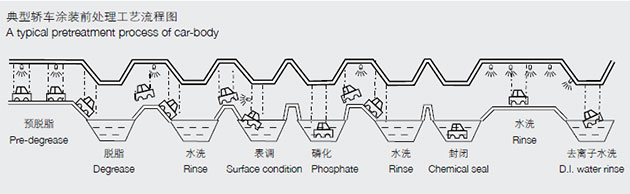

Phosphating is the core process of the pretreatment. The phosphate film is a porous and semi-conductive inorganic conversion layer formed by the reaction between steel/zinc coating and the phosphate solution. The formed layer can improve the adhesion of coating on the car body effectively; meanwhile supply the car an excellent under-film corrosion resistance and waterproof property. The most universal way to obtain the phosphating layer is to use a tri-cation(containing Zn, Mn, Ni) waterborne system and a full-dip process. The resulted crystalline layer with low zinc ratio has already been considered as a standard process of the pretreatment of ED-coating, and applied widely in auto industry for more than 40 years.

The forming process of phosphate layer is quite complicated, a mixture of a series of chemical reactions and electro-chemical reactions and can be described briefly with the reaction formulae below.

| Crystal size (¦Ìm) |

Film weight (g/m2) |

Main characteristics |

|---|---|---|

| 3~7 | 2~5 | Fe contained Main components are Me3(PO4)2·4H2O and Zn2Fe(PO4)2·4H2O P ratio>90% Excellent water and alkali resistance |

| 3~7 | 2~5 | No Fe contained Main component is Me3(PO4)2·4H2O Me: Zn, Mn, Ni Mn and Ni should be added into the layer to improve the under-film corrosion resistance |

| 3~7 | 3~8 | A little Fe contained Under-film corrosion resistance is better than that of GI |

| 3~7 | 1~3 | A kind of Pre-phosphate layer, treated at EGL Main Components and properties are similar to the layers treated at paintshop of automobile manufacturers Remained after re-phosphate at the paintshop of automobile manufacturers |