Welding

Spot welding

Spot welding has been widely used in industry as a kind of joining method for steel sheets, especially in automotive industry. There have thousands of spot welds in one car. The quality of spot welds had important influence on the properties of car. The spot welding technology of galvanized steel was different compared with that of the cold rolled steel without zinc coatings. With the wide application of galvanized steel in automotive industry, to know about the spot welding technology and weldability of galvanized steel would be very important.

Spot welding method

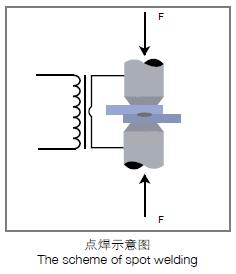

Spot welding belongs to the electrical resistance welding method which use electrical resistance to heat the base metal to form the welded joints which usually adopted the lap joints. Generally speaking, there have three continuous phases during the spot welding process. The first is to hold specimen together between two electrodes; the second process is to heat the welding area to certain temperature range by electrical circuit; the third process is to cool the specimen under the pressure of electrode force. During the spot welding process, the specimen was deformed under the pressure of electrodes with certain diameters and formed the electrical circuit only in the welded area. As a result, there have high current density in the welded area.

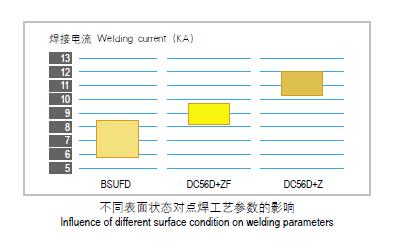

As for spot welding, galvanized steel demonstrates different welding technology compared with that of cold rolled steel without zinc coatings. The difference is caused by the coatings. Zinc was firstly melted and formed with zinc ring. As a result, the real contact area was increased and the current density was decreased. The welding current for the galvanized steel was higher than that of cold rolled steel without zinc coating in order to obtain the same diameter of nugget.

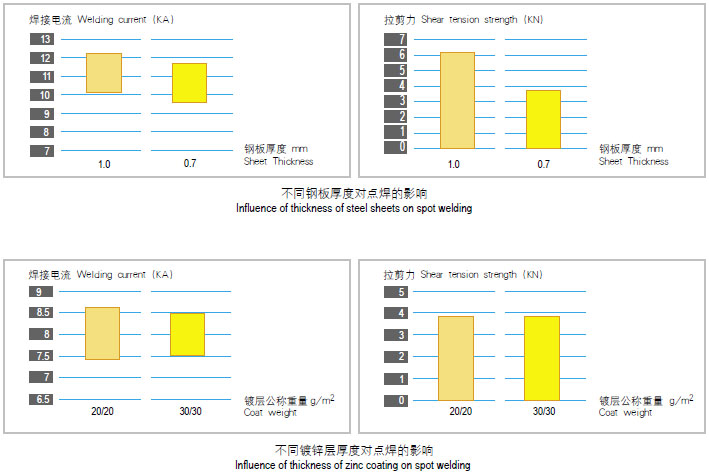

With the increase of zinc thickness while the other parameters are on the same condition, the minimum welding current Imin will increase and the maximum welding current Imax will decrease. This will lead to the decrease of welding lobe.

With the increase of thickness for steel sheets while the other conditions are the same, the welding current will increase but the width for the welding current lobe varies little. However, the shearing strength for the spot welds changes greatly.

The influence of welding current on the static strength of welds is great. The static strength of welds increase with the welding current within the welding lobe. In the area near to the bottom of welding lobe, the increase rate of static strength was higher than that of the area near to the top of welding lobe.

In order to obtain the qualified nugget size and strength of welds, the welding time and welding current can compensate within the certain range. For the spot welds with qualified strength, the welding parameters can choose the higher welding current with the short welding cycle time or the lower welding current with the long welding cycle time. This will depend on the properties and thickness of steel sheets.

With the increase of electrode force, there should have higher welding current or long welding time to keep the strength of welds in order to compensate the influence of decreased electrical resistance. By using this welding condition, it is beneficial to improve the stability of the strength of welds. Too lower electrode force can cause splash while too higher electrode force can cause deep dent of welding area. On both situations, the strength of welds would be decreased.

With the increase of the edge size for the electrode face, the contact area between the electrodes and specimen would increase, the current density would decrease. As a result, the nugget size would decrease. This will lead to the reduction of capacity for welds to sustain the load. With the deformation and wear of electrodes, the contact area would also increase. This would also lead to the reduction of strength for the spot welds.

The typical spot welding technology for automobile steel sheets

The bottom of welding current is according to the minimum qualified nugget size. The top of welding current is according to the appearance of splash or electrode-to-sheet sticking.

Typical properties of welded joints of automobile steel sheets

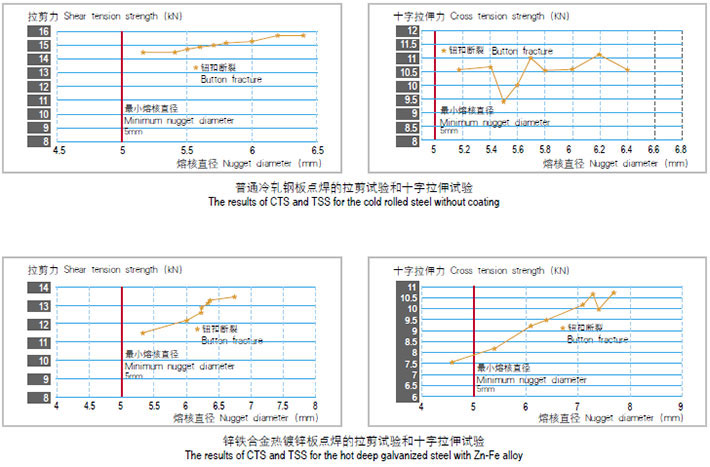

The strength of welded joints for spot welding was evaluated by shearing load and cross tension load. The ratio value of cross tension load with shearing load (K=Fn/Fs) was used to evaluate the ductility of welded joints. The tension load was obtained by cross- tension stress test while the shearing load was obtained by shear-tension test.

Laser tailor welded blanks for automobiles

Laser was the new technology that appeared in the sixties of the last century. Laser processing was widely used in the automobile, aerospace, mechanical, electrical and medical industry. The rapid development of automotive industry promoted the development of laser processing technology. Tailor welded blanks are defined as two or more separate pieces of flat material, dissimilar thickness, and/or mechanical properties, jointed together before forming to provide customized and superior qualities in the finished stamping.

The benefits of laser tailor welded blanks

1. The different combinations of different materials. Laser tailor welded blanks just use laser technology to join the different steel, thickness and coating condition together to meet the demand of car designer.

2. The complete forming by the combinations of automobile parts. By using tailor welded blanks, the combination of blanks which was formed independently before the appearance of tailor welded blanks was realized. The precision of car body structure can be improved and a lot of press equipment and working procedures can be saved.

3. The improvement of safety and reliability for structural parts. Continuous laser welding was used instead of spot welding. The structural integrity was improved. And more thick and high strength steel were used in some certain locations. The safety and reliability of structural parts were improved.

4. Potential to produce wide width automobiles. Automobile industry shows great concern on the wide width steel sheets while the width of steel sheets were constrained by the roller machine. Tailor welded blanks can solve this problem.

4. Potential to produce wide width automobiles. Automobile industry shows great concern on the wide width steel sheets while the width of steel sheets were constrained by the roller machine. Tailor welded blanks can solve this problem.

The application of tailor welded blanks

The benefits of tailor welded blanks were shown as high quality, high efficiency and low cost. In the project of Ultra Light Steel Auto Body, there have 16 tailor welded blanks in one car. As a result, the number of automobile parts was reduced 20%, the weight of the car was reduced 25%. Tailor welded blanks had been widely used in the application of door inner, rail, floor panel and pillar, etc..